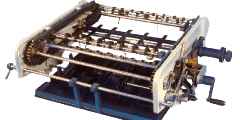

Even pressure between plate and blanket cylinder guarantees even high speed reliable output to prolong plate life. Convenience of operation charecteries the overall performance of IMPRINTA, We improve machines under practical working conditions until their optimum overall function is ensured. All thing is complemented under highly modern manufacturing conditions with quality control at all stages. The three cylinder arrange at a 90 angle eliminate shocks caused by sheet release or pressure on/off.

IMPRINTA incorporates 3 cylinder design for efficient and reliable printing. Independent adjustments are possible on master, blanket and impression cylinders.

Suction feed system is a well known universal feeding system with DOUBLE SHEET DETECTOR. It provides smooth feeding and prevent irregularities. Its characteristic features are high production reliability, precision of sheet alignment and simple operation.

Cylinder mounted grippers provides you good registration, Easy to operate pressure setting according to paper thickness. Photocell operating impression onoff system.

Ink section with total 9 or 11 rollers including 2 Foam & 3 Osilating rollers. P.S. Plate or Polyster Master mounting on Plate cylinder is very easy. Total 4 damping rollers including one Oscillators & 1 foam roller. Dempening foam roller is Gear driven gives accurate water film on the plate.

Chain delivery system in Contrast to Conventional Chute Delivery System in Small Offest Printing on Various paper thickness & paper size. Delivery pile has auto lowering facilities. Jogging systems gives perfact stack of printed sheet.

STURDY CONSTRUCTION

HIGHEST PRODUCTIVITY

THREE CYLINDER

DOUBLE SHEET DETECTOR

INK CLEANUP ATTACHMENTS

SKIP FEEDING DEVICE